Tungsten Parts

We are a professional supplier of tungsten products. Because of the hardness of tungsten, the process to manufacture tungsten parts is very complex. Only with high professional technology and rich experience can high-precision tungsten parts be produced. We can provide high quality and high precision tungsten fabricated parts according to the drawings customers provided.

Tungsten Fabricated Parts

Tungsten fabricated parts have high hardness. In addition, it has the properties of good wear resistance and heat resistance. Tungsten machined parts have high density, excellent electrical conductivity and thermal conductivity; tungsten machined parts can be used at temperatures up to 2400 ℃.They can also be made into tungsten fasteners, tungsten components, tungsten crucible, tungsten busbar bracket, tungsten conductor, tungsten busbar shoulder bolt, tungsten pin,tungsten standoff, tungsten heat shield, tungsten radial heat shield, tungsten power leg, tungsten spacer, tungsten shoulder screw, tungsten support plate, tungsten thumb nut, tungsten heater mount, tungsten heater base, tungsten accessory, tungsten casing, distribution valve bodies, rocket nozzles, gas pipelines, throat linings, armor piercing bullets, etc.

Tungsten Parts for Ion Implantation

Tungsten parts are used in ion implanters. As we all know, ion implanter is a very important device to make integrated circuits. Tungsten machined parts are the key component of ion source system in the semiconductor ion implanter for restraining and shielding ionizing rays. Our ion implanted tungsten parts have high density, high purity and uniform internal structure;Most ion implantation machines with tungsten parts are used in the semiconductor industry; We can produce tungsten parts of ion implanters according to customers' drawings.

Tungsten Seed Holder

The temperature of the conductor joint at both ends and the seed crystal holder can exceed 2000 ℃. High quality tungsten and molybdenum, stainless steel and other materials are good materials for tungsten seed holders.Tungsten seed holder is widely used in vacuum furnace and sapphire crystal growth furnace.

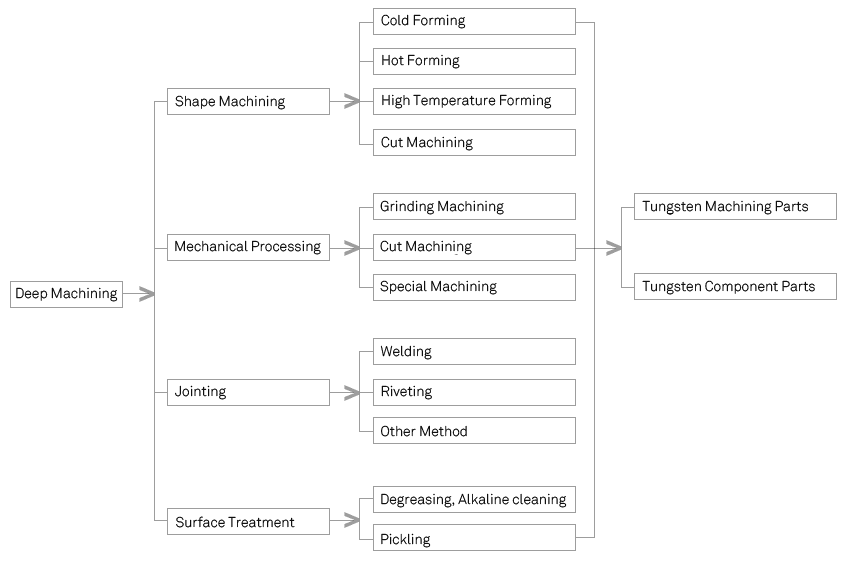

Tungsten machining/Tungsten fabrication

| Common Surface Treatment | |

| Electrolytic polishing | Remove surface scratches and cracks during machining |

| Oxidation method | Tungsten is oxidized in air to remove carbon layers or surface scratches |

| The injection method | Solving scratch or crack in the treatment process |

| Grinding method | |

Package Inspection

After the production is completed, we will conduct quality inspection and provide the quality inspection sheet which includes the material name, chemical composition analysis, mechanical properties, dimensions, etc. Our products are packed in specialized export wooden cases. All the products in the cases are separated by moisture-proof paper.If you would like to purchase tungsten parts from China, please don't hesitate to Contact Us.