Molybdenum and Tungsten Boats Carriers

Introduction of Molybdenum Boat

When

molybdenum boat is used in

high temperature furnace, it is one of the utensils used to hold workpieces. It can be used as a carrier and related parts. Why do we choose the refractory metals like

molybdenum and

tungsten as carriers in high temperature furnaces? Because molybdenum, tungsten and their alloys are not easy to deform at high temperature. The operating temperature of molybdenum and its alloy boat is about 1700-2000 ℃ while that of pure molybdenum boat is generally 1100 ℃, and that of TZM boat and ML boat is 1700-2000 ℃. Molybdenum, tungsten and their alloys are better and cleaner than graphite. If we want to improve the boat's high temperature strength and broaden its applicability, we can dope a certain amount of rare earth elements into pure molybdenum. The molybdenum alloys used to make boats are mainly

TZM and ML. TZM and ML not only have ten times the creep resistance of pure molybdenum, but also have excellent ductility. According to the customer's drawings and requirements, we can produce molybdenum boat by cutting, folding, riveting, welding and precision machining to the

molybdenum plate with a thickness of 3-6mm.

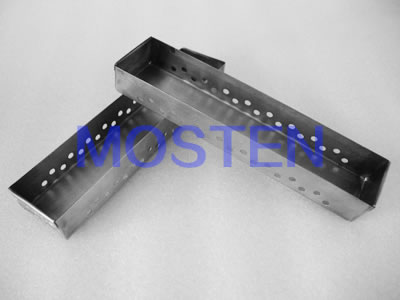

Shapes of Molybdenum Boat

Molybdenum boat can be made into different shapes such as circle, rectangle, square and trapezoid.

Applications of Molybdenum Boat

Our boat products have strong stability and corrosion resistance. Molybdenum boat can be manufactured with pure molybdenum or molybdenum alloy. In addition to being used in high temperature furnace, molybdenum boat can also be used as vacuum heat evaporation boat in coating process, electronic and electrical engineering, sintering of capacitor, sintering of nuclear fuel and widely used in rare earth industry. Compared to

molybdenum crucible, molybdenum boat has simpler structure and lower cost.

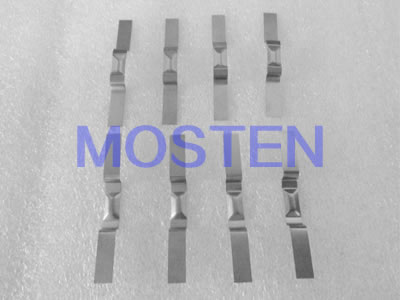

| Tungsten Boat Type |

| Model Number |

Thickness |

Width |

Length |

| NO. 207 |

0.2 mm |

7 mm |

100 mm |

| NO. 215 |

0.2 mm |

15 mm |

100 mm |

| NO. 308 |

0.3 mm |

8 mm |

100 mm |

| NO. 310 |

0.3 mm |

10 mm |

100 mm |

| NO. 315 |

0.3 mm |

15 mm |

100 mm |

| NO. 413 |

0.4mm |

13 mm |

50 mm |

| NO. 525 |

0.5 mm |

25 mm |

78 mm |

If you would like to purchase molybdenum and tungsten boats carriers from China, please don't hesitate to

Contact Us.