Molybdenum Rod & Bar

We are a professional supplier of molybdenum rod. We own excellent facilities including hot rolling mills and four-high cold rolling mills. Molybdenum bars are divided into two categories: one is used to make finished bars, the other is used to make semi-finished bars for drawing wires. There are two methods to process molybdenum rod: Swaging and groove rolling. Because we have exquisite processing technology, our molybdenum rod has the advantages of high electrode strength, high oxidation temperature resistance, strong corrosion resistance and long service life. We can provide high quality products in required size according to request of the customer. The surface of our product is smooth and free of impurities, delamination and cracks. We have passed ISO9001 certification.

Molybdenum Rod

The surface of our molybdenum rod has silver gray metallic luster. Its density is close to the theoretical density of 10.2g/cm3. Our molybdenum rod has good mechanical properties and uniform internal structure.Molybdenum rods are widely used as heating elements, outgoing lines and support rods in high-temperature furnaces. They are also used as the electrodes and bolts in rare-earth smelting industry and applied in the manufacturing of domestic and optical glass.

Molybdenum Bar

Our molybdenum rod is processed by vacuum annealing. Its purity is more than 3N.Molybdenum rods are widely used in electric vacuum parts, gas pipes, heating electrodes in the glass industry, and lamp holders in the lighting industry.

| Diameter of Our Regular Molybdenum Wire, Rod, Bar | |||

| Material | Shape | Diameter inch | Diameter mm |

| Moly | Molybdenum Wire | 0.003" | 0.0762 mm |

| Moly | Molybdenum Wire | 0.004" | 0.1016 mm |

| Moly | Molybdenum Wire | 0.005" | 0.127 mm |

| Moly | Molybdenum Wire | 0.006" | 0.1524 mm |

| Moly | Molybdenum Wire | 0.007" | 0.1778 mm |

| Moly | Molybdenum Wire | 0.008" | 0.2032 mm |

| Moly | Molybdenum Wire | 0.009" | 0.2286 mm |

| Moly | Molybdenum Wire | 0.01" | 0.254 mm |

| Moly | Molybdenum Rod/Bar | 0.02" | 0.508 mm |

| Moly | Molybdenum Rod/Bar | 0.03" | 0.762 mm |

| Moly | Molybdenum Rod/Bar | 0.05" | 1.27 mm |

| Moly | Molybdenum Rod/Bar | 0.1" | 2.54 mm |

| Moly | Molybdenum Rod/Bar | 0.2" | 5.08 mm |

| Moly | Molybdenum Rod/Bar | 0.3" | 7.62 mm |

| Moly | Molybdenum Rod/Bar | 0.5" | 12.7 mm |

| Moly | Molybdenum Rod/Bar | 1" | 25.4 mm |

| Moly | Molybdenum Rod/Bar | 1.5" | 38.1 mm |

| Moly | Molybdenum Rod/Bar | 2" | 50.8 mm |

| We can produce the molybdenum wires, rods and bars according to your requirement. | |||

Molybdenum Support Rod

There are two methods of producing molybdenum rods: surface grinding and surface turning machining. We can produce molybdenum heating elements according to customers' drawings. The purity of molybdenum rod can reach 3N5 and its density can reach 9.8g/cm3. The maximum working temperature of molybdenum rod in vacuum or reduction environment is 1700 ℃.Molybdenum rod is an important part in high temperature vacuum furnace. Under higher temperature environment, rare earth and lanthanum doped molybdenum and molybdenum rod can be used.

Swaged Molybdenum Rods

Our forged molybdenum bar has the high melting point of 2610 ℃. The forged molybdenum bar can be used at high temperature. It has good conductivity and tensile strength. The forged molybdenum bar has the characteristics of low vapor pressure and low coefficient of thermal expansion; the maxlength of a single forged molybdenum bar we produced can reach 20 meters.Forged molybdenum rod is widely used in electric heating elements, lighting industry, electronic industry and semiconductor industry. And the forged molybdenum rod can also be used as the lamp bracket, power tube components and the base of silicon rectifier.

Sintered Molybdenum Bar

The sintered molybdenum bar is a heat-resistant heating element. It has the characteristics of high melting point, high purity and high density. At the temperature 1700 ℃, it is used in high temperature oxidizing environment.Sintered molybdenum rod is mainly used for molybdenum wire drawing, molybdenum rod forging and ceramic refractory industry.

| Pure Molybdenum and Molybdenum Alloy Wire, Rod, Bar | ||

| Standard | Type | Specification |

| ASTM B387 | Molybdenum 360 | Unalloyed vacuum arc-cast molybdenum |

| ASTM B387 | Molybdenum 361 | Unalloyed powder metallurgy molybdenum |

| ASTM B387 | Molybdenum Alloy 363 | Vacuum arc-cast molybdenum-0.5 % titanium-0.1 % zirconium (TZM) alloy |

| ASTM B387 | Molybdenum Alloy 364 | Powder metallurgy molybdenum-0.5 % titanium-0.1 % zirconium (TZM) alloy |

| ASTM B387 | Molybdenum Alloy 365 | Unalloyed vacuum arc-cast molybdenum, low carbon |

| ASTM B387 | Molybdenum Alloy 366 | Vacuum arc-cast molybdenum-30 % tungsten alloy |

| Standard ASTM B387 | ||||||

| Chemical Composition,% maximum | ||||||

| Element | Molybdenum Type 360 |

Molybdenum Type 361 |

Molybdenum Alloy Type 363 |

Molybdenum Alloy Type 364 |

Molybdenum Alloy Type 365 |

Molybdenum Alloy Type 366 |

| C | 0.030 | 0.010 | 0.010-0.030 | 0.010-0.040 | 0.010 | 0.030 |

| O | 0.0015 | 0.0070 | 0.0030 | 0.0300 | 0.0015 | 0.0025 |

| N | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 |

| Fe | 0.010 | 0.010 | 0.010 | 0.010 | 0.010 | 0.010 |

| Ni | 0.002 | 0.005 | 0.002 | 0.005 | 0.002 | 0.002 |

| Si | 0.010 | 0.010 | 0.010 | 0.005 | 0.010 | 0.010 |

| Ti | … | … | 0.40-0.55 | 0.40-0.55 | … | … |

| W | … | … | … | … | … | 27-33 |

| Zr | … | … | 0.06-0.12 | 0.06-0.12 | … | … |

| Mo | balance | balance | balance | balance | balance | balance |

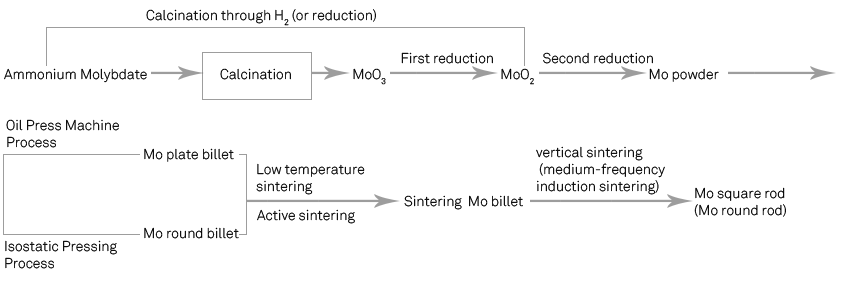

The production process of molybdenum rod

Packaging Inspection

After the production is completed, we will conduct quality inspection and provide the quality inspection sheet which includes the material name, chemical composition analysis, mechanical properties, dimensions, etc. Our products are packed in specialized export wooden cases. All the products in the cases are separated by moisture-proof paper.If you would like to purchase molybdenum rod & bar from China, please don't hesitate to Contact Us.