Molybdenum Sheet & Plate

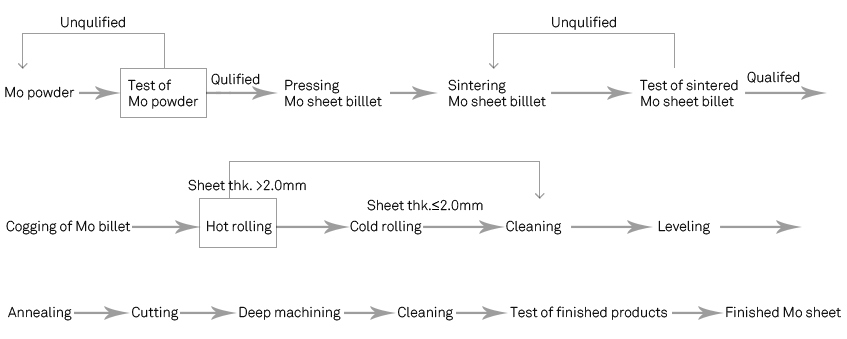

We are a professional supplier of molybdenum sheet, molybdenum block, molybdenum disc and sintered molybdenum plate. We own excellent facilities including hot rolling mills and four-high cold rolling mills. There are three processing techniques to manufacture molybdenum sheets: hot rolling, warm rolling and cold rolling. The production process involves stamping, bending, spinning, drawing and other processes. We also carried out vacuum annealing to the molybdenum sheets, blocks and discs. Our products have high density and stable internal structure, with high temperature resistance, good mechanical and process properties. According to different thickness, width and rolling process requirements, we can produce products with glossy, matte, satin or other specifications. Our products are free from scratches, impurity, delamination and cracks. We have passed ISO9001 certification. Our molybdenum sheet/plate has passed ASTM B386.

Due to its characteristics of high temperature and corrosion resistance, molybdenum sheet has the following uses: cover plate of sapphire growth furnace, heating belt, heating element of high temperature furnace, heat insulation layer of high temperature nuclear furnace. In addition, molybdenum also has good electric conductivity, which makes it the suitable material for making reflector (for automobile halogen lamp) and molybdenum electrode. There are other common uses of molybdenum sheet/plate, such as medical industry, crystal production, aviation, aerospace, nuclear energy, guided missiles, etc.

Molybdenum Sheet

The surface of our molybdenum sheet has silver gray metallic luster. Its flatness is less than 2%, purity more than 3N, and it conforms to ASTM B386 standard. Our molybdenum sheet has excellent mechanical properties and uniform internal structure.Molybdenum sheet is mainly used to produce vacuum furnace heat shield, molybdenum electrode, heating elements, sputtering target, and sapphire growth furnace components.

| Thickness of Our Regular Molybdenum Sheet | |||

| Material | Shape | Thickness inch | Thickness mm |

| Moly | Molybdenum Sheet | 0.01" | 0.254 mm |

| Moly | Molybdenum Sheet | 0.015" | 0.381 mm |

| Moly | Molybdenum Sheet | 0.02" | 0.508 mm |

| Moly | Molybdenum Sheet | 0.025" | 0.635 mm |

| Moly | Molybdenum Sheet | 0.03" | 0.762 mm |

| Moly | Molybdenum Sheet | 0.035" | 0.889 mm |

| Moly | Molybdenum Sheet | 0.04" | 1.016 mm |

| Moly | Molybdenum Sheet | 0.045" | 1.143 mm |

| Moly | Molybdenum Sheet | 0.05" | 1.27 mm |

| Moly | Molybdenum Sheet | 0.055" | 1.397 mm |

| Moly | Molybdenum Sheet | 0.06" | 1.524 mm |

| Moly | Molybdenum Sheet | 0.065" | 1.651 mm |

| Moly | Molybdenum Sheet | 0.07" | 1.778 mm |

| Moly | Molybdenum Sheet | 0.075" | 1.905 mm |

| Moly | Molybdenum Sheet | 0.08" | 2.032 mm |

| Moly | Molybdenum Sheet | 0.085" | 2.159 mm |

| Moly | Molybdenum Sheet | 0.09" | 2.286 mm |

| Moly | Molybdenum Sheet | 0.095" | 2.413 mm |

| Moly | Molybdenum Sheet | 0.1" | 2.54 mm |

| Moly | Molybdenum Sheet | 0.15" | 3.81 mm |

| We can produce the molybdenum sheets according to your requirement. | |||

Molybdenum Plate

Our molybdenum plates are manufactured through extrusion, forging, rolling and annealing. The density is between 10-10.2 g/cm3. The surface the plates has been machined with cold rolling and vacuum annealing.Molybdenum plates are applied in medical industry, sapphire growth furnace, aviation, aerospace, nuclear energy, guided missile, etc.

| Thickness of Our Regular Molybdenum Plate | |||

| Material | Shape | Thickness inch | Thickness mm |

| Moly | Molybdenum Plate | 0.2" | 5.08 mm |

| Moly | Molybdenum Plate | 0.25" | 6.35 mm |

| Moly | Molybdenum Plate | 0.3" | 7.62 mm |

| Moly | Molybdenum Plate | 0.35" | 8.89 mm |

| Moly | Molybdenum Plate | 0.4" | 10.16 mm |

| Moly | Molybdenum Plate | 0.45" | 11.43 mm |

| Moly | Molybdenum Plate | 0.5" | 12.7 mm |

| We can produce the molybdenum plates according to your requirement. | |||

Molybdenum Disc

The density of our molybdenum disc is 10.13g/cm3. Its surface is glossy and has metallic luster.It is mainly used in SCR diodes, connecting materials of transistors and thyristors, heat sink of LSI and hybrid circuits, heating sintering plate and baseplate.

| Thickness of Our Regular Molybdenum Disc | |||

| Material | Shape | Thickness inch | Thickness mm |

| Moly | Molybdenum Disc | 0.01" | 0.254 mm |

| Moly | Molybdenum Disc | 0.015" | 0.381 mm |

| Moly | Molybdenum Disc | 0.02" | 0.508 mm |

| Moly | Molybdenum Disc | 0.025" | 0.635 mm |

| Moly | Molybdenum Disc | 0.03" | 0.762 mm |

| Moly | Molybdenum Disc | 0.035" | 0.889 mm |

| Moly | Molybdenum Disc | 0.04" | 1.016 mm |

| Moly | Molybdenum Disc | 0.045" | 1.143 mm |

| Moly | Molybdenum Disc | 0.05" | 1.27 mm |

| Moly | Molybdenum Disc | 0.055" | 1.397 mm |

| Moly | Molybdenum Disc | 0.06" | 1.524 mm |

| Moly | Molybdenum Disc | 0.065" | 1.651 mm |

| Moly | Molybdenum Disc | 0.07" | 1.778 mm |

| Moly | Molybdenum Disc | 0.075" | 1.905 mm |

| Moly | Molybdenum Disc | 0.08" | 2.032 mm |

| Moly | Molybdenum Disc | 0.085" | 2.159 mm |

| Moly | Molybdenum Disc | 0.09" | 2.286 mm |

| Moly | Molybdenum Disc | 0.095" | 2.413 mm |

| Moly | Molybdenum Disc | 0.1" | 2.54 mm |

| Moly | Molybdenum Disc | 0.15" | 3.81 mm |

| We can produce the molybdenum discs according to your requirement. | |||

Sintered Molybdenum Plate

Our sintered molybdenum plate is sintered with high-purity molybdenum powder, which lays the foundation of our high-quality molybdenum sheet and disc. The sintered molybdenum plates are used in target processing and the manufacturing of vacuum heating furnace parts.

| Pure Molybdenum and Molybdenum Alloy Foil, Sheet, Plate, Disc | ||

| Standard | Type | Specification |

| ASTM B386 | Molybdenum 360 | Unalloyed vacuum arc-cast molybdenum |

| ASTM B386 | Molybdenum 361 | Unalloyed powder metallurgy molybdenum |

| ASTM B386 | Molybdenum Alloy 363 | Vacuum arc-cast molybdenum-0.5 % titanium-0.1 % zirconium (TZM) alloy |

| ASTM B386 | Molybdenum Alloy 364 | Powder metallurgy molybdenum-0.5 % titanium-0.1 % zirconium (TZM) alloy |

| ASTM B386 | Molybdenum Alloy 365 | Unalloyed vacuum arc-cast molybdenum, low carbon |

| ASTM B386 | Molybdenum Alloy 366 | Vacuum arc-cast molybdenum-30 % tungsten alloy |

| Standard ASTM B386 | ||||||

| Chemical Composition,% maximum | ||||||

| Element | Molybdenum Type 360 | Molybdenum Type 361 | Molybdenum Alloy Type 363 | Molybdenum Alloy Type 364 | Molybdenum Alloy Type 365 | Molybdenum Alloy Type 366 |

| C | 0.03 max | 0.010 max | 0.010-0.030 | 0.010-0.040 | 0.010 max | 0.030 max |

| O, max | 0.0015 | 0.0070 | 0.0030 | 0.0300 | 0.0015 | 0.0025 |

| N, max | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 |

| Fe, max | 0.010 | 0.010 | 0.010 | 0.010 | 0.010 | 0.010 |

| Ni, max | 0.002 | 0.005 | 0.002 | 0.005 | 0.002 | 0.002 |

| Si, max | 0.010 | 0.010 | 0.010 | 0.005 | 0.010 | 0.010 |

| Ti | … | … | 0.40-0.55 | 0.40-0.55 | … | … |

| W | … | … | … | … | … | 27-33 |

| Zr | … | … | 0.06-0.12 | 0.06-0.12 | … | … |

| Mo | balance | balance | balance | balance | balance | balance |

The production process of molybdenum sheet

Packing and Inspection

After the production is completed, we will conduct quality inspection and provide the quality inspection sheet which includes the material name, chemical composition analysis, mechanical properties, dimensions, etc. Our products are packed in specialized export wooden cases. All the products in the cases are separated by moisture-proof paper.If you would like to purchase molybdenum sheet & plate from China, please don't hesitate to Contact Us.